Exploring Opportunities for Occupational Safety Technicians

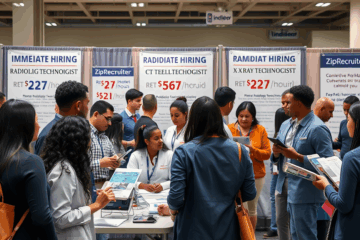

Safety Technician roles are gaining significant attention in today’s workforce, highlighting the vital importance of workplace safety across various industries.

Do right now and discover exciting job opportunities!

Apply now to start your new journey!

This article will delve into the projected growth of these positions, the essential functions technicians perform in mitigating risks, and the increasing demand for their expertise, particularly in regions like Georgia.

With an average of 18,200 openings expected each year over the next decade, the future looks promising for those aspiring to enter this field.

From on-the-job training to specialized roles, there is a wealth of opportunities awaiting future Safety Technicians.

Evolving Scope of Safety Technician Careers

The responsibilities of occupational safety technicians have significantly expanded as modern industries face increasingly complex workplace environments.

These professionals no longer function solely as compliance enforcers but are now essential contributors to proactive safety planning, program implementation, and risk mitigation strategies.

As industries such as construction, manufacturing, logistics, and even healthcare integrate advanced systems, safety technicians incorporate analytics, reporting tools, and preventive measures into daily operations.

Their evolving role ensures not only regulatory compliance but also the physical and mental well-being of workers, driving lasting improvements in workplace culture and productivity.

Demand for skilled occupational safety technicians continues to rise as organizations seek professionals capable of handling diverse safety responsibilities and adapting to dynamic operational needs.

Fueling this increase is an uptick in national and regional job openings, notably in high-growth areas like Georgia, where data from the Bureau of Labor Statistics underscores employment projections.

Occupational safety technicians are no longer limited to reactive roles, but instead are integral in developing systems that reduce hazards before incidents occur.

These shifting expectations create opportunities for technicians to specialize, seek certifications like the Occupational Hygiene and Safety Technician certification, and apply their expertise across a variety of sectors.

This momentum reflects a widespread commitment to safer, smarter workplaces that rely on the agility and insight of occupational safety professionals.

Sector-Specific Career Paths

Occupational safety technician opportunities are plentiful and vary significantly across major industries.

Technicians play a crucial role in implementing safety protocols and training within sectors such as manufacturing, construction, and healthcare.

Each environment presents unique challenges, requiring technicians to adapt their strategies to mitigate risks and enhance worker safety.

Construction and Infrastructure

Within construction and infrastructure, occupational safety technicians play a critical role in maintaining regulatory and procedural workplace safety.

These professionals monitor building sites daily, ensuring all personnel follow protocols designed to minimize exposure to hazardous materials, extreme heights, and heavy machinery risks.

Their responsibilities include performing safety audits, inspecting personal protective equipment, and guiding foremen and workers in implementing corrective measures when incidents or near misses occur.

By proactively identifying potential dangers, they reduce injury rates and contribute to a more productive and compliant work environment.

Safety technicians also collaborate closely with site engineers and compliance officers to ensure alignment with industry standards and federal safety regulations.

OSHA 30 certification and CPR/First Aid training are often mandatory to secure entry-level roles, helping candidates demonstrate readiness for safety protocols starting day one.

As infrastructure projects grow in both number and complexity, demand for qualified technicians continues to climb.

Regions such as Texas and Louisiana offer hundreds of active roles, reflecting a nationwide trend toward prioritizing workforce protection.

Technicians can pursue advancement by obtaining recognized certifications like the Construction Health and Safety Technician (CHST), which enables access to specialized supervisory roles.

Advancement may also include transitioning into managerial positions where they lead entire safety teams on multi-million-dollar projects.

Because of ongoing investment in public and commercial infrastructure, especially in states undergoing rapid development, career advancement in this field is both achievable and sustainable.

Manufacturing and Production

Manufacturing safety technicians in production facilities play a pivotal role in identifying and mitigating machine-related hazards.

They oversee operational compliance with safety protocols during maintenance, repair, and active production, ensuring systems like lockout/tagout are correctly implemented to prevent accidental machine startups.

Properly calibrated sensors and automation controls are monitored to reduce injury risks tied to high-speed equipment and moving parts.

Notably, safety technicians often collaborate with engineers and supervisors to assess ergonomic design and mechanical setups for opportunities to minimize strain and physical hazards for operators working on the line.

In addition to machine safety, technicians focus heavily on process safety management, especially in high-risk environments involving combustible materials or reactive substances.

They routinely conduct real-time inspections, hazard analyses, and preventive action plans that align with OSHA standards.

Facilities increasingly rely on digital tools and data monitoring, opening up avenues for technicians to specialize in safety analytics and system automation.

As they deepen expertise in these areas, not only do they prevent workplace incidents, but they also position themselves for career growth and advanced roles in safety program development and compliance leadership across manufacturing sectors.

Healthcare and Laboratories

Biological and chemical hazard management in healthcare and laboratory settings requires vigilant planning, a strong understanding of safety protocols, and the ability to adapt to evolving risks.

Occupational Safety Technicians play a pivotal role in developing and enforcing these safety measures to prevent contamination, infection, and accidents.

In clinical labs, they implement exposure control plans, monitor for compliance with CDC and OSHA guidelines, and ensure that all procedures involving hazardous substances prioritize employee health.

Additionally, technicians oversee the proper segregation and disposal of infectious materials and initiate training to uphold high safety standards across departments.

Understanding biological threats such as bloodborne pathogens or microbial agents, and chemical dangers like volatile solvents or toxic reagents, is essential to maintain operational safety.

Technicians must frequently audit facility practices and ensure the use of personal protective equipment and Class II biosafety cabinets when handling sensitive samples.

In more advanced environments, tools like chemical fume hoods and properly calibrated detection systems minimize inhalation risks.

With over 8,600 healthcare-related safety technician jobs available in Florida alone, it highlights the growing demand and critical nature of this profession.

Continuous education and field-specific certifications keep technicians current, empowering them to respond swiftly and effectively to any biological or chemical hazard encountered.

Energy and Utilities

Occupational safety technicians

in the energy and utilities sector face some of the most demanding environments, including high-voltage areas that pose extreme electric shock and arc flash risks.

Working around energized lines requires constant surveillance and precise documentation to ensure adherence to OSHA electrical safety standards (1910.

269), with even minor oversights potentially leading to fatal outcomes.

Technicians are responsible for implementing lockout/tagout procedures, overseeing grounding protocols, and maintaining proper PPE use—all while ensuring productivity in fast-paced utility operations.

Their role is critical for reducing incident rates, especially as many installations now involve dynamic renewable energy systems with increased complexity.

At the same time, technicians face the unique hazards of confined spaces commonly found in underground utilities, silos, and storage vaults.

These environments present oxygen-deficient atmospheres, toxic chemical exposure risks, and limited egress points, requiring careful atmospheric monitoring and coordinated entry procedures in line with OSHA 1910.

146 permit-required confined space regulation.

In remote energy sites—like wind farms or offshore platforms—limited access to emergency responders makes advanced situational awareness and proactive safety planning indispensable.

Companies are prioritizing skilled professionals, often using career platforms such as Bioenergy Career Map, to ensure staffing in these high-risk zones meets both operational and compliance needs effectively.

Advancement and Professional Development

Advancement opportunities for occupational safety technicians are plentiful, making ongoing education and professional development essential.

Through specialized training and certifications, technicians can enhance their skills and knowledge, positioning themselves for higher-level roles.

Continuous learning not only boosts career prospects but also contributes to the overall safety culture within their organizations.

Certification Pathways

Obtaining certifications significantly amplifies an occupational safety technician’s credibility and professional outlook.

Among the widely respected credentials is the OHST — Occupational Hygiene and Safety Technician — ideal for those focused on workplace hygiene and hazard mitigation.

Another solid choice is the CHST, suitable for technicians in construction environments.

For those aiming to progress toward full safety management roles, both the ASP and the CSP carry considerable weight in the industry.

Furthermore, the STS credential supports supervisors seeking to lead safety initiatives effectively.

Relevant certifications not only enhance hiring potential but also promote long-term career growth.

Leadership and Management Tracks

Advancing from a technical role to a leadership position in occupational safety often begins with accumulating extensive on-site experience and expanding responsibilities.

Many technicians demonstrate their readiness for leadership by leading safety briefings, managing incident investigations, and mentoring newer technicians.

These opportunities not only foster essential supervisory skills but also enable visibility among decision-makers.

Taking initiative to lead safety initiatives and showcasing problem-solving abilities often result in promotions to supervisory roles where responsibility over small teams and project coordination begins.

From there, gaining formal training enhances the trajectory.

Technicians pursuing programs like the Leadership in Safety Management certificate benefit from modern managerial strategies rooted in safety best practices.

These qualifications, combined with a proven track record, open the door to managerial roles overseeing compliance, developing policy, and shaping organizational safety culture.

Being entrusted with cross-department responsibilities marks a critical milestone, strongly indicating an organization’s confidence in a technician’s leadership capabilities.

Regional Demand and Job Outlook

The demand for occupational safety technicians is surging nationwide, with a projected 14% job growth from 2023 to 2033—more than double the average for all occupations

This notable increase stems from heightened regulatory compliance, broader safety awareness across industries, and rapid advancements in industrial technologies.

According to the

Bureau of Labor Statistics Occupational Outlook”>U.S. Bureau of Labor Statistics

Although opportunities exist in every state, certain regions now offer especially high employment prospects due to workforce development investments and concentrated industrial expansion.

For instance, several southern and western states report consistent demand in both private and public sectors, particularly within manufacturing, construction, and energy.

- Georgia — rapid industrial growth and supportive regulations

- Texas — expansive construction projects and oil & gas presence

- California — strong labor protections and tech-driven safety initiatives

- Alabama — regional job development programs and industrial clusters

- Illinois — centralized logistics hubs and manufacturing demand

Emerging and Alternative Opportunities

Emerging career paths for occupational safety technicians extend beyond traditional worksite inspections as new fields demand specialized knowledge and innovative approaches.

Environmental safety is expanding rapidly, especially as industries contend with stricter compliance related to pollution control and climate resilience.

Technicians are increasingly collaborating with environmental engineers and sustainability officers to implement protocols that protect ecosystems while ensuring worker health.

This includes indoor air monitoring and managing hazardous materials in green-certified buildings, driven by both regulations and corporate responsibility initiatives.

As organizations embrace digital transformation, remote risk monitoring is becoming a critical area of growth.

Safety technicians now utilize intelligent sensor networks and AI-driven predictive maintenance tools to prevent accidents before they happen.

Companies are investing in systems highlighted by platforms like Aware360’s Safety Tech Trends to automate hazard detection and monitor lone workers in real-time.

This shift empowers technicians to shift from reactive inspections into proactive guardianship of company operations.

Another growing path is safety software integration, where technicians operate at the intersection of compliance, training, and digital infrastructure.

Mastering platforms like ASSP’s learning management systems and AI-enhanced training simulations is becoming essential.

These tools allow safety teams to create immersive risk scenarios and track performance across dispersed workforces.

As companies implement data-driven safety programs, technicians who can bridge the gap between safety and software are becoming indispensable assets.

In conclusion, the demand for skilled Safety Technicians is on the rise, reflecting a broader commitment to enhancing workplace safety.

With diverse opportunities available, aspiring professionals have the chance to make a significant impact in their communities and industries.

0 Comments